|

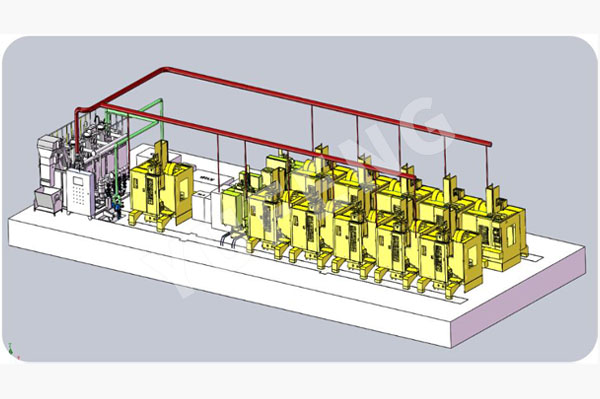

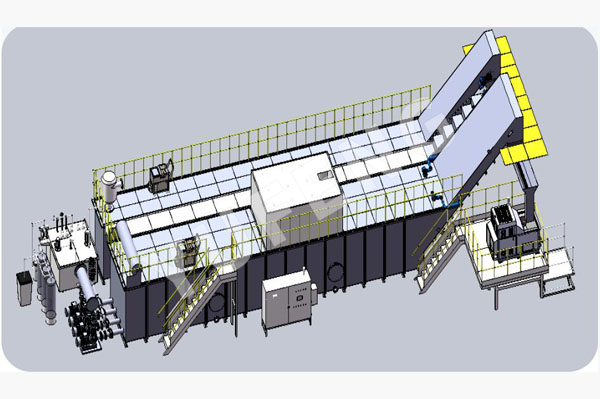

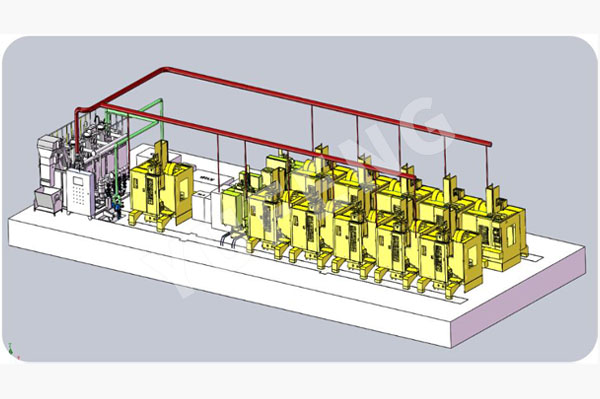

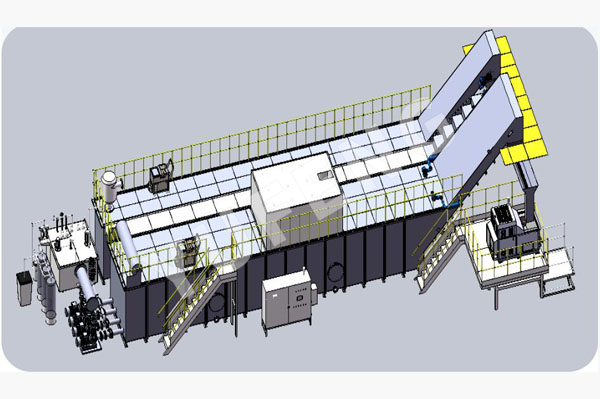

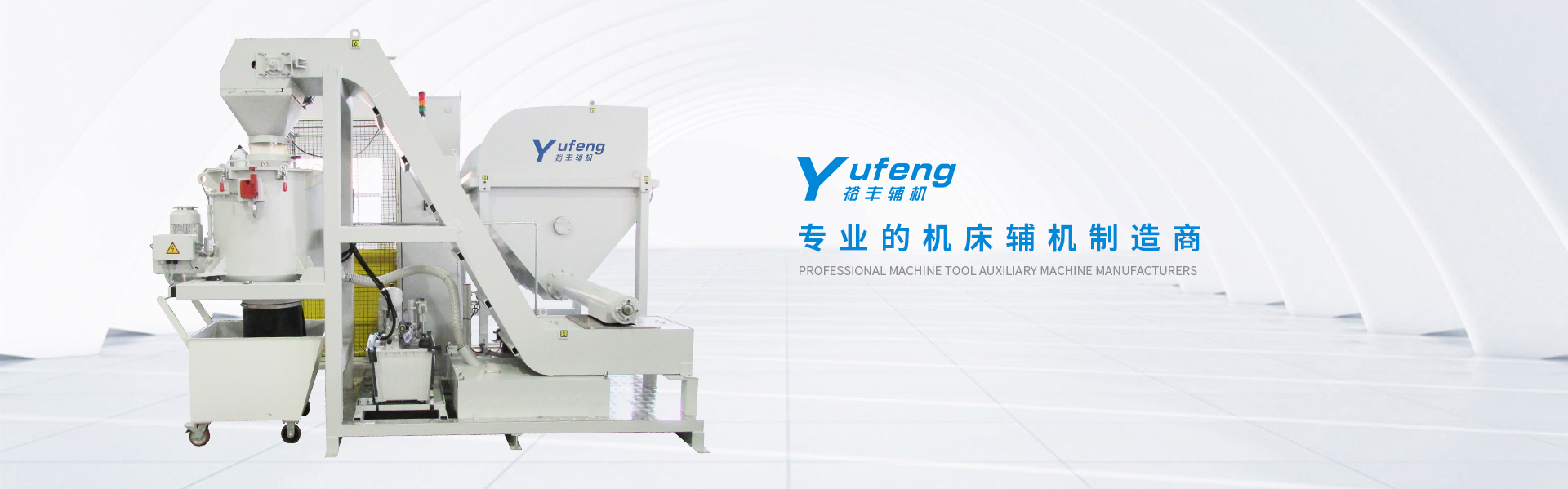

切屑液集中處理系統

|

|

切削液集中處理系統主要用于機床加工線的冷卻液的集中過濾與集中冷卻。主要組成為刮板排屑機、負壓紙帶過濾機、冷卻液配液裝置、供液泵組、冷卻液防腐系統、PLC電器控制系統、回液泵站等。

切削液集中過濾系統的供液和回液大體有三種方案:一是全部架空走管,二是架空供液、地溝回液;三是供液管和回液管都在地溝中,空中沒有管道。

集中過濾系統可配油水分離、凈化再生和比例加液自動補水裝置,為長期保持冷卻液和清洗液的有效性能和車間衛生提供有效解決方案,節省費用,創造優良的生產環境。 冷卻液集中處理系統采用負壓式紙帶過濾方式,變頻恒壓節能供液。 高精度、大流量,可24小時連續供液;變頻泵恒壓供液;全自動控制運行、模擬工況顯示、故障顯示及報警;設備運行可靠穩定,故障率低;防腐系統大大延長乳化液的使用壽命;

方案的選擇取決于廠房條件和切屑性質,我們會按用戶的具體工況設計解決方案。

Coolant central filtering system is mainly used in machine processing line for central cooling and filtrating. It is composed of scraper chip conveyor, negative pressure paper band filter.coolant distriboutor,liquid-supply pump group,coolant anti-corrosion system,PLC electric control system and coolant-retum pump etc.

The liquid supply and return are divided into three schemes: one is all pipelines are overhead: second is overhesd supply,liquid return in trench;Third is both liquid-supply pipeline and return return pipeline are in trench .The schemes are differenent because of the differentce of workshop conditions and chips .We can design as users’ requirements.

This device can be used with oil separator,purification regeneration system and automatic proportion liquid adding device.It supplies a better method for the effectiveness of coolant and the cleanness of workshop .The system is not only cost-saving but also creates anexcellent working environment.

The coolant central filtering system uses negative pressure paper band filtering method. It can energy-efficient supply liquid under frequency ,constant pressure condition.

This system is high precision,large flow rate and can supply liquid for 24 hours; Frequency- conversion pump can supply liquid by constant voltage.It runs automatically,has analogue display,failure display and alarm. The device runs stable and has few faults.

|

Tags:切屑液集中處理系統廠家,切屑液集中處理系統價格

當前位置 :

當前位置 :