|

集中排屑處理系統

|

|

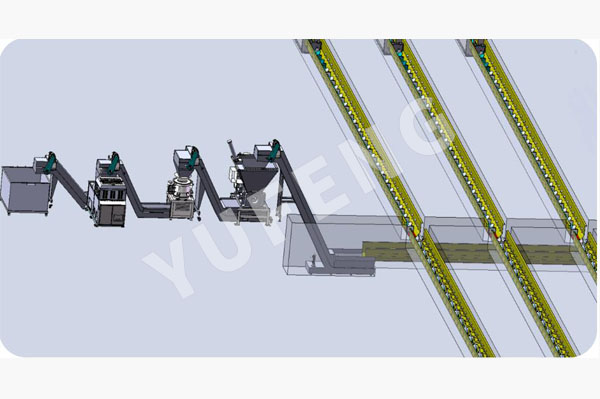

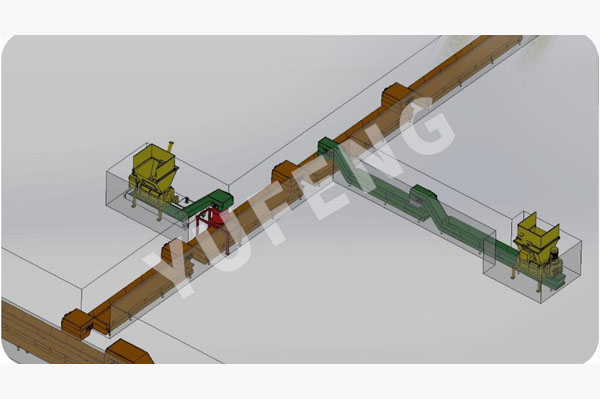

集中排屑系統是指在一個車間內設置一套或多套主排屑裝置。同時在柔性生產線和機床下另設支線排屑裝置。工作時,切屑先由機床自帶的排屑器送至支線排屑裝置,然后經由支線排屑裝置運至主排屑裝置內,后由主排屑裝置將其運至指定區域,切屑可進行斷屑粉碎、離心甩干、打包壓塊。整個過程自動控制,高效穩定,可節省工人每天清理切屑時間,大大降低了工人的勞動強度,同時也保證了生產車間的美觀和整潔。

Centralized chip removal system refers to one or more sets of main chip removal devices in a workshop. At the same time, a branch line chip removal device is installed under the flexible production line and the machine tool. When working, the chips are first sent to the branch line chip removal device by the chip removal device provided by the machine tool, and then transported to the main chip removal device through the branch line chip removal device, and then transported to the designated area by the main chip removal device. The chips can be broken and crushed, centrifugally dried, and packed. The whole process is automatically controlled, efficient and stable, which can save the time for workers to clean chips every day, greatly reduce the labor intensity of workers, and also ensure the beauty and cleanness of the production workshop.The centralized chip removal system is mainly used for the collection and treatment of iron chips in the machining production line. The centralized chip removal line can be used to collect and process all kinds of rolled, round, strip and block chips. During the whole chip removal process, the chain plate type, spiral type or stepping type chip removal device can be selected for the branch line chip removal device and main chip removal device according to the site working conditions and equipment layout. The tail end of the conveying system is combined with the pulverizer, drying machine, briquetting machine, and packer for centralized treatment of iron filings.

|

Tags:集中排屑處理系統廠家,集中排屑處理系統價格

當前位置 :

當前位置 :